Core Veneer from Dragon Hub Wood is a premium, durable veneer sourced from the core of mature rubber trees in Vietnam. Ideal for furniture, interior design, and architectural applications, it offers exceptional quality and aesthetic appeal, making it a top choice for global export.

Description

Rubber Core Veneer: Premium Quality from Dragon Hub Wood

Welcome to Dragon Hub Wood, where we offer a premier selection of Rubber Core Veneer, a high-quality product that stands out in the global market. Our Rubber Core Veneer is meticulously crafted to meet the highest standards of performance and sustainability, making it an ideal choice for a wide range of applications. As a leading supplier and exporter from Vietnam, we are committed to delivering exceptional products to wholesalers and businesses worldwide. This comprehensive description will delve into the features, benefits, and applications of Rubber Core Veneer, highlighting why Dragon Hub Wood is the preferred choice for your veneer needs.

Understanding Rubber Core Veneer

Rubber Core Veneer, also known as rubber wood veneer, is a type of veneer made from the core of rubber trees (Hevea brasiliensis). This veneer is prized for its durability, versatility, and aesthetic appeal. The rubber tree, primarily grown for latex production, is harvested for its wood once it reaches the end of its productive life cycle. The core wood of the tree is then processed into veneer sheets, which are used in a variety of applications due to their unique properties.

1. Production Process

The production of Rubber Core Veneer involves several key steps:

- Harvesting: Rubber trees are harvested when they reach the end of their latex-producing lifespan. The core wood is carefully selected to ensure high quality and suitability for veneer production.

- Preparation: The harvested wood is debarked and cut into logs, which are then transported to a processing facility.

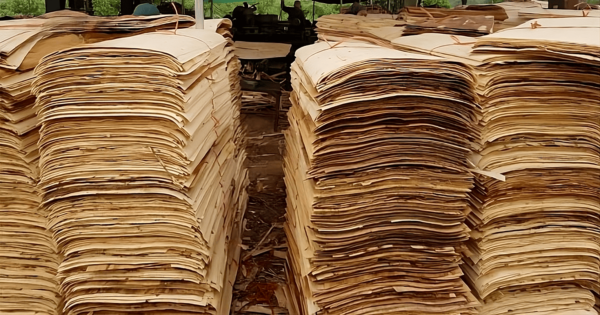

- Slicing: The logs are sliced into thin veneer sheets using specialized equipment. The slicing process ensures that the veneer retains its natural grain patterns and characteristics.

- Drying: The veneer sheets are dried to reduce moisture content and prevent warping. This step is crucial for maintaining the stability and quality of the veneer.

- Finishing: The dried veneer sheets are sanded, treated, and finished to enhance their appearance and durability. This may include applying protective coatings or stains to achieve the desired look.

Benefits of Rubber Core Veneer

Rubber Core Veneer offers numerous advantages that make it a popular choice for various applications:

1. Sustainability

One of the key benefits of Rubber Core Veneer is its sustainability. Rubber trees are harvested after their latex production has ceased, making use of wood that would otherwise be wasted. This process aligns with sustainable forestry practices and reduces environmental impact. The use of rubber wood contributes to a more sustainable supply chain, as it maximizes the utility of the tree and supports responsible resource management.

2. Durability

Rubber Core Veneer is known for its durability and strength. The core wood of the rubber tree is dense and robust, making it suitable for applications that require long-lasting materials. The veneer is resistant to wear and tear, making it ideal for high-traffic areas and furniture that experiences frequent use.

3. Aesthetic Appeal

The natural grain patterns and color variations of Rubber Core Veneer give it a distinctive and attractive appearance. The veneer can be finished in various ways to enhance its natural beauty, including staining, polishing, and coating. Its aesthetic appeal makes it a popular choice for decorative applications, including furniture, cabinetry, and interior paneling.

4. Versatility

Rubber Core Veneer is highly versatile and can be used in a wide range of applications. Its flexibility allows it to be applied to various surfaces and substrates, including wood, MDF, and plywood. The veneer can be used for both residential and commercial projects, making it a versatile choice for designers and builders.

5. Cost-Effectiveness

Compared to other types of wood veneers, Rubber Core Veneer offers a cost-effective solution without compromising on quality. Its availability and sustainable production methods contribute to its competitive pricing, making it an attractive option for wholesalers and manufacturers looking to source high-quality veneer at a reasonable cost.

Dragon Hub Wood: Your Trusted Supplier

At Dragon Hub Wood, we are dedicated to providing top-quality Rubber Core Veneer to clients around the world. Our commitment to excellence and sustainability is reflected in every aspect of our operations:

1. Quality Control

We adhere to stringent quality control measures throughout the production process to ensure that our Rubber Core Veneer meets the highest standards. Our quality control team inspects each batch of veneer for consistency, appearance, and performance, ensuring that our clients receive only the best products.

2. Sustainable Practices

Sustainability is a core value at Dragon Hub Wood. We are committed to responsible forestry practices and the efficient use of resources. Our Rubber Core Veneer is produced from rubber trees that have reached the end of their latex-producing lifecycle, minimizing waste and supporting environmental stewardship.

3. Wholesale and Export

As a leading exporter of Rubber Core Veneer from Vietnam, Dragon Hub Wood serves clients across the globe. Our extensive export network allows us to deliver high-quality veneer to wholesalers and businesses in various regions. We offer flexible shipping options and efficient logistics to ensure timely and secure delivery.

4. Customer Service

We are dedicated to providing exceptional customer service to our clients. Our experienced team is available to assist with inquiries, provide product information, and offer support throughout the purchasing process. We strive to build long-lasting relationships with our clients by delivering outstanding products and personalized service.

Applications of Rubber Core Veneer

Rubber Core Veneer is used in a variety of applications, including:

- Furniture: Rubber Core Veneer is commonly used in the production of furniture, including tables, chairs, and cabinets. Its durability and aesthetic appeal make it an ideal choice for high-quality furniture pieces.

- Cabinetry: The veneer is used in cabinetry to create elegant and functional storage solutions. Its versatility allows it to be applied to various cabinet surfaces, enhancing the overall look and feel of the cabinetry.

- Interior Paneling: Rubber Core Veneer is used for interior paneling in both residential and commercial settings. It adds a touch of sophistication and warmth to walls, ceilings, and partitions.

- Decorative Accents: The natural beauty of Rubber Core Veneer makes it a popular choice for decorative accents, including trim, moldings, and inlays. Its ability to be finished in various styles allows for creative design applications.

Rubber Core Veneer vs. Plywood: A Comparative Perspective

Plywood, a synthetic material made from recycled plastics, is often compared to Rubber Core Veneer due to its durability and low maintenance. However, there are key differences between the two:

- Source Material: Rubber Core Veneer is made from natural wood residues, making it a renewable and biodegradable option. Plywood, on the other hand, is made from recycled plastics, which are non-renewable resources.

- Environmental Impact: Rubber Core Veneer contributes to a reduction in waste and supports sustainable forestry practices. Plywood, while reducing plastic waste, does not offer the same level of resource renewal and emissions reduction.

- Applications: Rubber Core Veneer is primarily used for interior applications such as furniture and paneling, while Plywood is used for outdoor furniture and decking. The suitability of these materials depends on the specific needs of the project.

Conclusion

Dragon Hub Wood is proud to offer premium Rubber Core Veneer that combines quality, sustainability, and versatility. As a leading supplier and exporter from Vietnam, we are committed to delivering exceptional products to wholesalers and businesses worldwide. Our Rubber Core Veneer is produced with the highest standards of craftsmanship and environmental responsibility, making it the ideal choice for a wide range of applications.

Explore our range of Rubber Core Veneer and discover how Dragon Hub Wood can provide you with top-quality veneer solutions for your next project. Whether you’re looking for durable furniture materials, elegant cabinetry, or decorative accents, our Rubber Core Veneer offers a superior choice that meets your needs and exceeds your expectations.